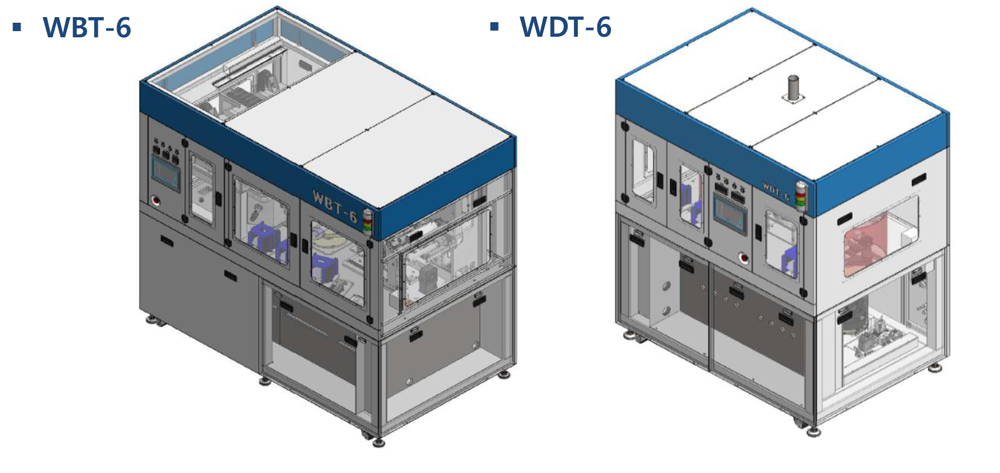

WBT - 6 |

Device Wafer is transferred to Robot, Roll Lamination proceeds after removal of 1st liner of Tape, Round cutting is performed by knife, Wafer removed by 2nd liner, Bonding by Support Plate and Roll Press in vacuum chamber

![]()

Specification

Dimension | W : 2350 D : 1300 H : 2000 |

Through-Put | 40min/1cassette(25wafers ≒ 37wafers/hr |

Cuttig Accuracy | ±0.5mm for wafer edge |

Position Accuracy | ±0.5mm in XY directions |

Vacuum | 100mtorr or Low |

Bonding | Void Free (Vacuum Process) |

WDT - 6 |

The bonded wafer is transferred to the vacuum chuck reversing robot,and the hot plate is de-bonded, the support plate is returned to the vacuum chuck, and the Thin Wafer is returned to each robot of the Bernoulli chuck

![]()

Specification

Dimension | W : 16000 D : 1100 H : 1800 |

Through-Put | 40min/1cassette(25wafers ≒ 37wafers/hr |

TR1 | 180° Reverse (Vacuum Grip. Flip Motor) |

TR2 | Bernoulli (Thin Wafer Handling) |

Heating Temp Accuracy | ±2.5°C [RT~250°C] |

Exhaust Temp | 100 ~ 180°C |

SI (System Innovation Co,.Ltd.) | ceo : Kim Jong Hoon

TEL : 031-8059-2864 | FAX : 031-8059-2865

Address : Jeongnamsandan 1-gil, Jeongnam-myeon, Hwaseong-si, Gyeonggi-do, Republic of Korea

Copyright ⓒ 2018 SYSTEMI.CO.KR, All Rights Reserved.